Filling & closing

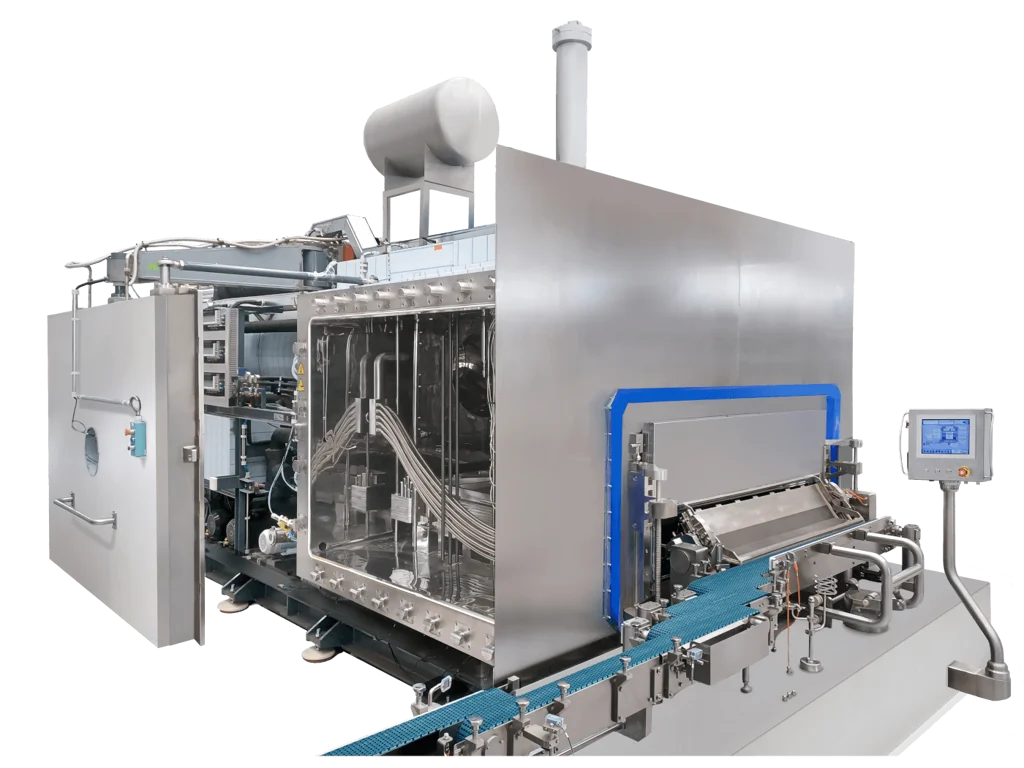

Our vial filling systems combine flexibility and precision: we offer a wide range of technologies, including valve piston and peristaltic pump, mass-flow, rolling diaphragm pump, time-pressure filling – or a combination of all within our combi filling station. They all enable you to fill your products in a highly customized way. Tool-less format changes and a variable number of filling heads increase your flexibility. Subsequent sealing offers a variety of methods such as pick and place or continuous stoppering – without the use of vacuum. Continuous capping with high speeds completes the safe and reliable closing process. Quality is increased with 100% check weighing (IPC) and inline inspection systems such as empty vial inspection, stopper position, crimp quality, or print check control.

Benefits:

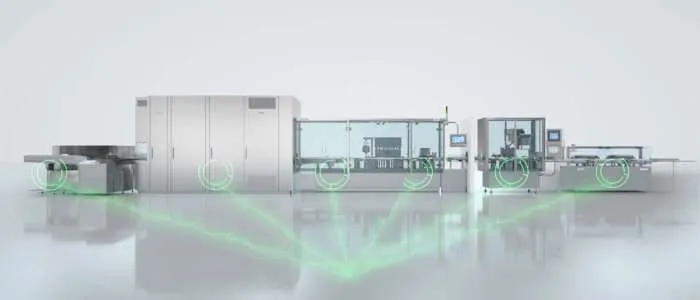

- Modular machine set up with barrier systems – all integrated and harmonized from a single source

- Various integrated inline inspection systems

- From small batches to high speeds with 600 vials per minute, including 100 % IPC